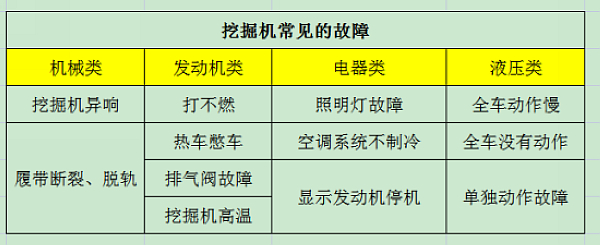

Excavators undertake high-intensity,

extended-duration tasks in earthmoving construction, mining operations, and

infrastructure development. Under complex working conditions and frequent

operation, equipment inevitably experiences various malfunctions. Timely and

accurate diagnosis of fault causes, coupled with standardized corrective

actions, is crucial for ensuring stable equipment operation and minimizing

downtime risks. This article categorizes and analyzes common excavator faults

based on practical usage scenarios, providing users with valuable technical

guidance.

I. Common Mechanical Failures

· Abnormal Noise Issues

Unusual noises occurring during excavator

rotation, boom extension/retraction, working device operation, or near engine

cylinder liners are typically linked to insufficient lubrication or localized

wear. Accurately pinpoint the noise source first, then promptly replenish

grease at relevant hinge points and friction areas to prevent further component

damage from dry friction.

· Track Breakage or Derailment

Prolonged operation on rough terrain, improper turning maneuvers, or failure to clear debris from tracks can cause excessive wear or derailment. Inspect track tension, the condition of welded areas beneath track guards and idler wheels. Replace worn or deformed components promptly to prevent secondary damage.

II. Engine System Failures

· Failure to Start (No Ignition)

If the excavator fails to restart after

stalling during operation, common causes involve issues with the fuel pump or

injectors. On-site troubleshooting can involve cooling the fuel pump with water

for preliminary assessment. If the engine starts successfully after cooling,

calibrate the fuel pump and inspect the injector functionality.

· Hot Engine Stalling

When the machine experiences power loss or

stalls while hot, accompanied by black smoke, this is often due to clogged fuel

system, intake system, or engine “three filters” (air, fuel, oil). If caused by

increased internal leakage in the high-pressure fuel pump, professionally

calibrate the pump and inspect the regulator, valve assembly pressure, and

internal component wear.

· Exhaust Valve Malfunction

If the exhaust system exhibits abnormalities, prioritize inspecting the exhaust valve assembly for damage. If the assembly is intact, examine the condition of the exhaust valve filter element. This filter element is typically recommended for replacement every 1000 hours to ensure unobstructed exhaust flow.

III. Electrical System Failures

· Lighting System Failure

Non-functioning lights are often caused by

a blown high-voltage fuse or wiring faults. If a blown fuse is detected, replace

it with an identical specification to prevent secondary failures from

mismatched components.

· Air Conditioning System Not Cooling

If refrigerant leakage occurs due to wear

on the expansion valve's temperature sensor, replace the expansion valve.

Follow standard procedures for vacuum extraction, pressure retention testing,

and precise refrigerant charging to restore normal cooling performance.

· Engine Shutdown Warning Displayed

Upon this warning, first verify that engine

oil has been changed at scheduled intervals and that oil levels are adequate.

Simultaneously inspect the oil pressure sensor and its wiring harness for open

circuits or short circuits.

IV. Hydraulic System Malfunctions

· Sluggish Vehicle Operation

Slow response typically relates to abnormal

pressure in the main relief valve. Inspect the relief valve for blockages or

wear, then adjust or replace based on findings.

· Complete System Inactivity

This fault requires starting with the pilot

system. Check pilot pressure and main pump pressure. The troubleshooting

sequence should include the electrical system (e.g., safety lock switches,

solenoid valves, fuses) and the hydraulic system (pilot pressure, main relief

valve, hydraulic pump, return filter, etc.) to accurately pinpoint the source

of the fault.

· Isolated Movement Malfunction

When a specific movement significantly

slows down or fails completely while others function normally, focus on

inspecting the spool valve. Verify its sealing integrity, disassemble to check

for scratches or wear, and ensure the ball bearing moves freely within the

valve body. If abnormalities are found, repair or replace the valve immediately.

Excavator malfunctions rarely stem from a

single cause but result from the combined effects of prolonged operating

conditions, maintenance practices, and operating methods. Systematic

inspections and standardized maintenance of mechanical, engine, electrical, and

hydraulic systems not only promptly eliminate potential hazards but also

effectively extend equipment lifespan and enhance overall construction

efficiency. Users are advised to establish regular inspection and maintenance

logs. For complex faults, promptly engage professional technicians to ensure

the equipment remains in optimal operating condition.

2021-06-27

2021-09-30

2021-01-13

2021-01-14

2021-08-10

2021-12-31

2021-12-14

2021-01-15